Climat & Energy

The actions undertaken to reduce GES (Greenhouse Gas) emissions are grouped around 5 axes:

1- Energy efficiency:

Aware that cement is an energy-intensive industry, we have always considered energy consumption as a key issue that has been taken into account from the design of our sites. We have naturally chosen processes, technologies and equipment that consume less energy: high performance coolers, latest generation separators, widespread use of high efficiency turbines for process fans, variable frequency drives for the main motors, etc;

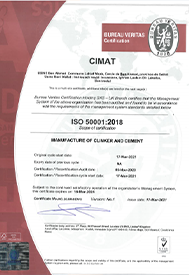

Continuous improvement in the optimization of energy consumption and consideration of regulatory requirements led us to implement an energy efficiency management system that was certified in 2020 in accordance with the ISO 50001 v2018 standard

2- Renewable energy:

As early as 2018, we began supplying our Ben Ahmed and Beni Mellal plants with renewable energy from wind power via PPA (Power Purchase Agreements). Today, our factories operate at 85% with wind energy. This conversion and massive use of renewable energy has enabled us to avoid the emission of 210,618 tons of CO2 in 2019.

The site of Ben Ahmed is supplied with 95% of wind energy

The site of Beni Mellal is supplied with 74% of wind energy

KMAD gain on the electric bill in 2019

Of renewable energy consumed in 2019 at the two sites

3- Waste valorization:

Also in our environmental approach, we recover waste as alternative fuels and substitute materials in the kilns of our cement plants (co-processing or co-treatment). In 2019, we co-processed more than 80,000 Tons of ordinary industrial waste and biomass in our kilns, thus avoiding the emission of more than 150,000 Teq of CO2.

« For the vast majority of environmental impacts, the study shows that it is less harmful to the environment to use industrial waste as an alternative fuel for cement production than to process it in waste incinerators. The use of a ton of waste produces energy that would have been provided by other sources without the addition of that ton of waste, including fossil fuels that contribute to global warming. »

Source Extract from TNO's study on « Treatment of industrial waste in cement kilns or incinerators ».

4- Reduction of the clinker/cement factor:

Reducing the proportion of clinker in cement (clinker/cement factor or K/C) is an important issue in reducing global GES emissions. This reduction has been achieved through 2 processes:

- Substitution of a fraction of clinker with fly ash from coal combustion in thermal power plants. The valorization of this fly ash was a nice ecological alternative to its burial.

800,000 Tons of fly ash were consumed between 2011 and 2019 in our production sites.

- Clinker mineralization: a process based on the incorporation of infinitesimal doses of fluorine in the production of clinker which improves its reactivity and consequently, reduces its use in cement

5- Logistics optimization

Transport is an undeniable and important source of GES emissions on a global scale, therefore the optimization of logistics is a necessity. We have therefore invested 140 million DH in connecting our plant in Ben Ahmed to the national rail network, thus using a means of transport characterized by its extremely low level of GES emissions.

Environmental Commitment

The actions undertaken to reduce GES (Greenhouse Gas) emissions are grouped around 5 axes......

Co-processing has been a priority for CIMAT since the design of our plants, ......

We consider water stress and the scarcity of water resources......

Co-processing has been a priority for CIMAT since the design of our plants, ......