Services & Support

Logistics Department

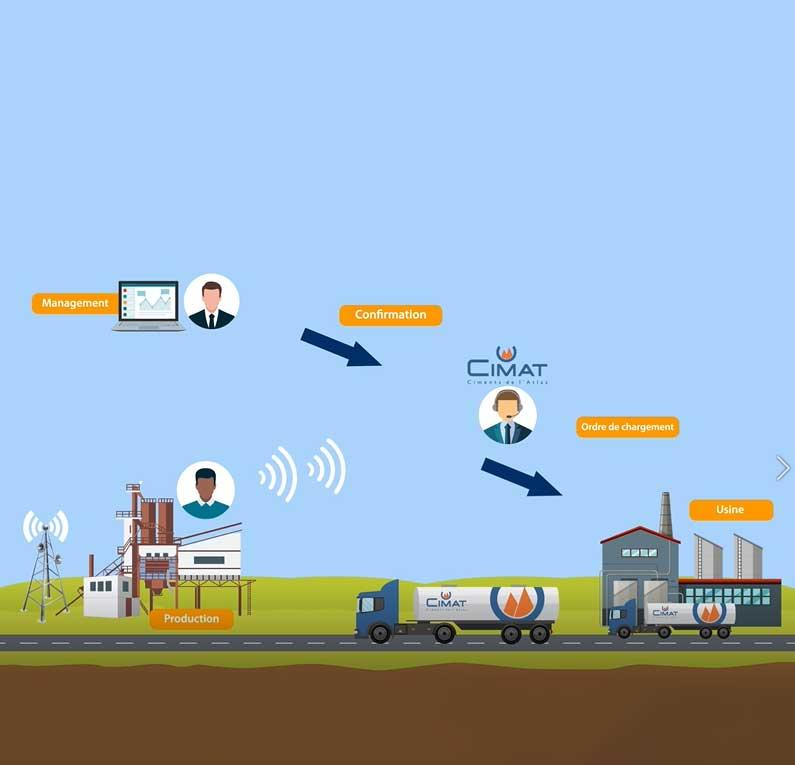

Our logistics team accompanies you on a daily basis to deliver in the best conditions thanks to 4 solutions/services.

THE ACTIVITY RENDERED

CIMAT offers its customers the possibility to load its products directly by their own means in its shipping points, or to be delivered by CIMAT's logistic means directly in their building sites or warehouses.

CIMAT has a fleet of tanker trucks (for bulk cement) or trays (for bags or palletized bags), well sized and ready to deliver from the plants, wherever the desired location.

All the deliveries are followed by the geo-location tool, and CIMAT puts all the human and material means to ensure the respect of the deadlines wished by the customers.

CIMATRACK: ADVANCED GEOLOCATION

Follow-up of your deliveries in real time.

CIMAT's digitalization process aims to offer customers reliable information and continuous updates.

The application (web + mobile) has been designed so that each user, depending on his or her nature, can access the deliveries within his or her perimeter to know their progress in real time, react if necessary and even contact the driver if necessary.

AUTOMATIC NOTIFICATION OF DELIVERIES:

In order to make the sharing of information concerning deliveries more reliable and automated, CIMAT has set up an automatic notification of deliveries by SMS and email.

With each outbound delivery from the various shipping locations, whether outbound or inbound, customers receive an automatic notification sent to the contact information specified by the customers.

CIMAT Smart Silos

"Manage your bulk cement inventory and monitor your stock status in real time via alerts."

A custom-made solution for demanding professionals

In order to better help its customers control their bulk cement inventories, Ciments de l'atlas has developed a customized solution to efficiently manage cement stock and avoid stock-outs, a major enemy of the BPE and prefab industry.

The current management methods allow at best to have a theoretical quantity of the stock, knowing that this value will depend on several elements of which mainly a discipline without fault in the seizure of the entries, a precision of the means of measurement (scales cement), two parameters which are missing rather often.

In order to estimate the real stock, whether for a periodic inventory or planning of production / replenishment, current measurement methods are based on the analysis of the gravity of the sound emitted by the silos in response to hammer blows. This method is not very accurate and presents significant safety risks. And if we forget to make the measurement in time, the result can be catastrophic.

This is why Ciments de l'Atlas has designed a solution called "Cimat Smart Silos". The solution consists of installing weight sensors (extensometers) at the feet of the silos that allow reading the micrometric displacements (compression, traction) of the silo supports and converting these movements into weight.

The weight measurement is displayed locally at the production unit operator and is also sent via a transmission device to the processing server, which can:

Display in real time, on the application, the stock status in the different connected silos, Send alerts (SMS and emails) if the replenishment thresholds (configurable according to the consumption rate and the distance from the nearest delivery point) are exceeded.

Display the consumption history of the silo over a given period to be able to reconstitute the history of the supplies, the ranges and the rate of consumption...

The customer's employees can be classified by geographical area and/or type of activity to allow customers to efficiently manage the access rights to be given to their employees.

The application is offered free of charge to Ciments de l'Atlas customers on the web and mobile.